L&T Group Websites

- Corporate

- Corporate – Arabic

- GreenTech

- Heavy Engineering

- Hydrocarbon

- LTIMindtree

- L&T Construction

- L&T Construction & Mining Machinery

- L&T Finance

- L&T Howden

- L&T Hydraulics

- L&T Infrastructure Finance Company Limited

- L&T Institute of Project Management

- L&T Technology Services

- L&T Kuwait Construction

- L&T MBDA Missile Systems Limited

- L&T Metro Rail (Hyderabad) Limited

- L&T-MHI Power Boilers

- L&T-MHI Power Turbine Generators

- L&T Precision Engineering and Systems

- L&T Realty

- L&T-Sargent & Lundy Limited

- L&T Special Steels and Heavy Forgings

- L&T-SuFin

- L&T Valves Limited

- Nabha Power Limited

- Power

- L&T Public Charitable Trust

- Rubber Processing Machinery

- Shipbuilding

- L&T Skill Trainers Academy

Power Block Auxiliaries

All Solutions- Pictures

Coal Pulverisers

L&T-MHI Power Boilers Private Limited also provides large capacity coal pulverisers which use Mitsubishi Power’s advanced Mitsubishi Rotary Separator to achieve higher fineness directly resulting in improved combustion efficiency and lower emissions. Since these are large capacity pulverisers, they reduce the number of pulverisers that are required to be used with the boilers, effectively reducing maintenance costs for customers.

Critical Piping

L&T has a large pool of experienced piping engineers, specialised software, and state-of-the-art manufacturing set-up for carrying out critical piping work for power plants. Our capability includes alloy steel piping for high pressure and high temperature steam conditions, feed water systems and complete power cycle piping in boiler and turbine islands.

Foundry

L&T has set up a heavy foundry with a capacity of 2500T per annum. The foundry would be capable of producing castings of up to 60 MT, making L&T Energy-Power only the second company in India with such capability. The foundry will cater to the heavy casting needs of supercritical boilers, turbines, and related auxiliaries.

Heat Exchangers

L&T, through the Heavy Engineering Division (HED) of L&T Group, also supplies heat exchangers and vessels for power plants. HED has long proven experience in design, manufacturing and delivery of high-pressure and low-pressure heat exchangers, condensers and de-aerators.

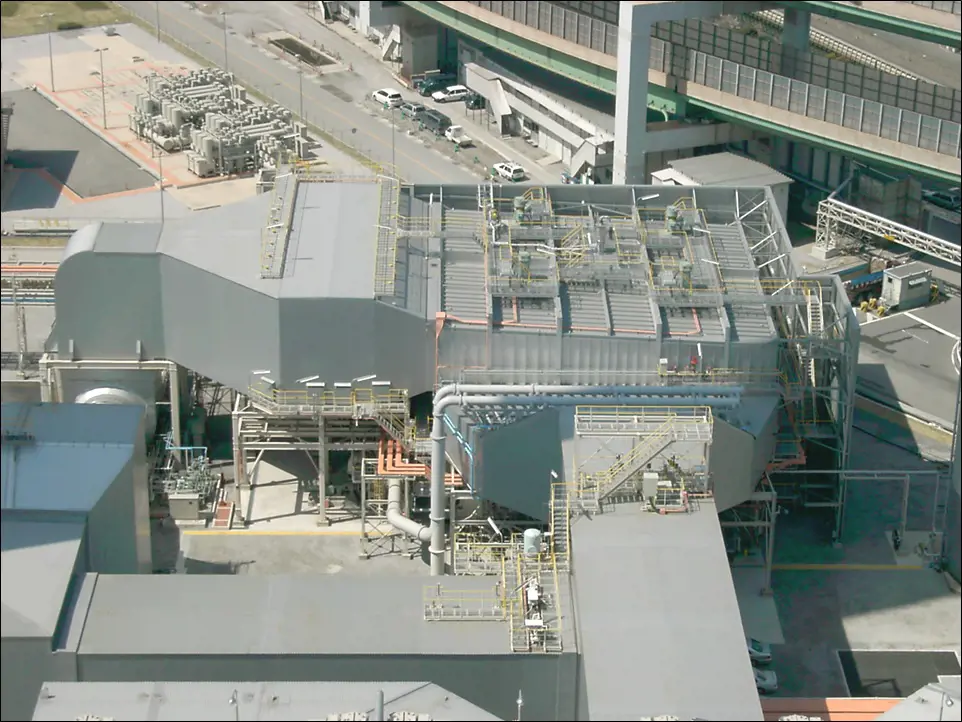

Variable Pitch Axial Fans

Variable pitch axial fans are used where high volumes, high aerodynamic performance and precise flow control are required, and where reliability and continuous running for extended periods are demanded. They are the fans of choice in critical applications for large boilers within the power industry, where they are used in both primary air, forced draught and induced draught applications.

L&T Howden provides for design, engineering, manufacture and supply of axial fans to thermal power plants ranging between 100 MW to 1200 MW.

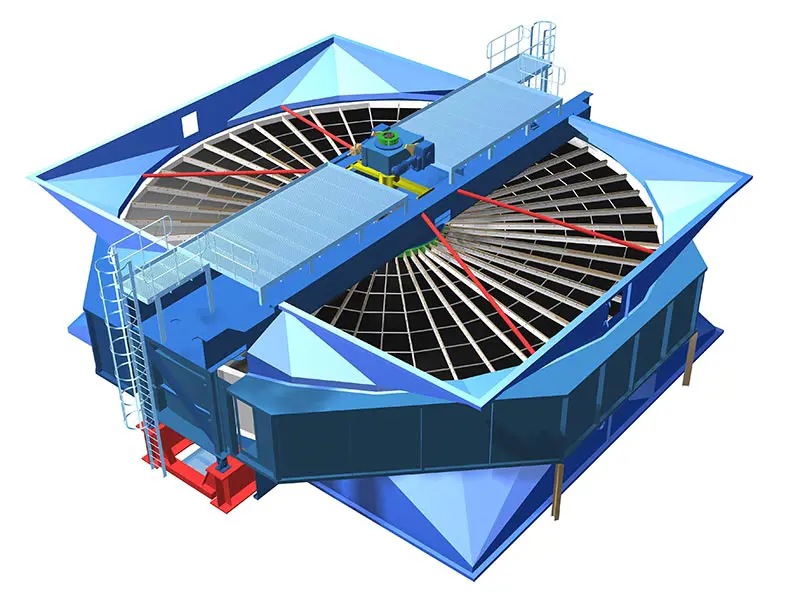

Rotary Air Preheaters

Power boilers require highly efficient and reliable air preheaters to ensure optimum performance. The core of the preheater, the heat exchange surface, is composed of several hundred tonnes of metal plates known as elements. As the preheater slowly rotates, at around 1-2 rpm, the elements collect heat from the hot gas stream being discharged from the boiler and then transfer it to the cold air stream entering the boiler. This can provide improved efficiency and boiler performance, thus leading to reduced CO2 emissions from the boiler.

L&T Howden provides for design, engineering, manufacture and supply rotary air preheaters to thermal power plants ranging between 100 MW to 1200 MW.