L&T Group Websites

- Corporate

- Corporate – Arabic

- GreenTech

- Heavy Engineering

- Hydrocarbon

- LTIMindtree

- L&T Construction

- L&T Construction & Mining Machinery

- L&T Finance

- L&T Howden

- L&T Hydraulics

- L&T Infrastructure Finance Company Limited

- L&T Institute of Project Management

- L&T Technology Services

- L&T Kuwait Construction

- L&T MBDA Missile Systems Limited

- L&T Metro Rail (Hyderabad) Limited

- L&T-MHI Power Boilers

- L&T-MHI Power Turbine Generators

- L&T Precision Engineering and Systems

- L&T Realty

- L&T-Sargent & Lundy Limited

- L&T Special Steels and Heavy Forgings

- L&T-SuFin

- L&T Valves Limited

- Nabha Power Limited

- Power

- L&T Public Charitable Trust

- Rubber Processing Machinery

- Shipbuilding

- L&T Skill Trainers Academy

Capabilities

L&T Power’s capability spectrum embraces Coal and Gas-based projects. Our expertise encompasses virtually every aspect of design, engineering, manufacture, construction and project management.

Ultra-supercritical / Supercritical Technology

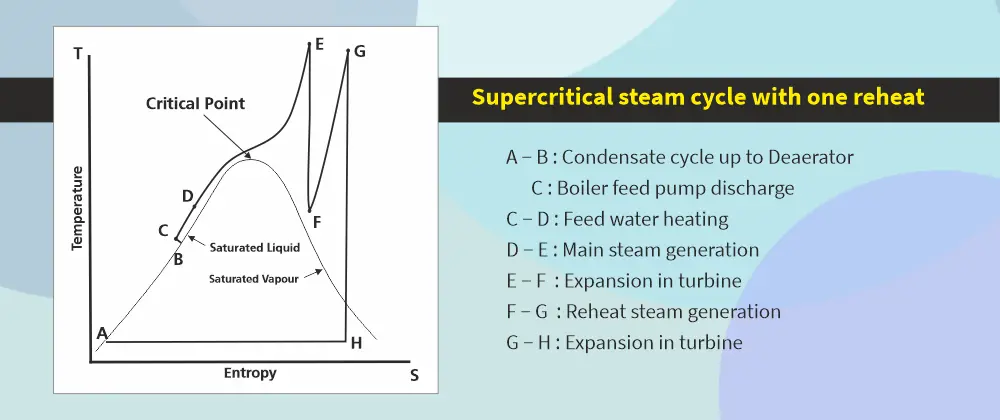

The term "supercritical" refers to main steam operating conditions, above the critical pressure of water i.e. 221.5 bar. The significance of the critical point is that at pressure ≥ 221.5 bar, the difference between steam and water vanishes. All water converts to steam in a flash, as there is no phase change process above critical pressure.

Ultra-supercritical (USC) / supercritical (SC) plants are designed to operate above the critical pressure of water. USC / SC boilers are once-through, in which the feed water enters the boiler and comes out of the boiler as steam without any circulation. The feed water enters the economiser (point D) and flows through various heating sections (i.e. economiser, water walls, superheater) and main steam exits at the end (point E).

Typically, SC units operate at 247 bar main steam pressure, 565ºC main steam temperature and 593ºC reheat steam temperature while USC boilers operate at higher temperatures and pressure than that of supercritical units. USC units operate at main steam pressure of 270 bar, 600ºC main steam temperature and 600ºC reheat steam temperature.

History

Supercritical technology has evolved over the past 30 years. Advancements in metallurgy and design concepts have made supercritical technology units extremely reliable and highly efficient. Modern supercritical technology is largely available in Japan and Europe for boilers & turbines ranging upto 1000 MW.

Advantages of Ultra-supercritical / Supercritical Technology

Higher Efficiency

Supercritical steam conditions improve the turbine cycle heat rate significantly over subcritical steam conditions. The extent of improvement depends on the main steam and reheat steam temperatures for the given supercritical pressure. Advanced supercritical units improve the plant efficiency by about 5% over the conventional subcritical units. This results in fuel savings of up to 5%.

Ultra-supercritical units’ efficiency is higher by about 3.5%, resulting in further fuel savings of up to 3.5% over supercritical units.

Operational Flexibility

Ultra-supercritical / supercritical technology units also offer flexibility of plant operation such as:

- Shorter start-up times

- Faster load change flexibility and better temperature control

- Better efficiency even at part load due to variable pressure operation

- High reliability and availability of power plant

Construction Capability Unit

The Construction Capability Unit (CCU) of L&T Power plays a key role in the execution of Flue Gas Desulphurisation (FGD) projects. Apart from this, CCU also executes general civil works and cooling tower (EPC basis) packages for coal-based thermal power plants.

With a repository of construction knowledge, CCU has built capable teams. The team at head office (HO) spearheads these projects till they are handed over to customers by ensuring timely availability of drawings, documents, resources and technical support to all sites. The HO team is also armed with Construction Methods & Planning Cell (CMPC) which provides schemes for heavy lift erection, formwork, chimney construction using slipform technology, NDCT construction using jumpform technology and identifies requirement of strategic construction equipment for all projects - coal, gas, nuclear and FGD.

Quality Management Capability Centre

The Quality Management Capability Centre (QMCC) ensures consistency in its offerings at all the stages of the project lifecycle and for all projects of L&T Power. The key objective of the Centre is to ensure a customer-centric organisation through the institutionalisation of processes and systems, and to meet the quality benchmarks of products and services against requirements established in contractual documents.

The QMCC also ensures sustainable continual improvement towards achieving customer satisfaction. This is achieved with the vision of ‘Doing it right first time, every time & in time’ being deployed through capability building, defect prevention & benchmarking, continual improvement and rendering prompt & efficient quality services.

The QMCC gives L&T Power an unmatched edge when it comes to end-to-end building and management of large power projects.

Central Planning and Monitoring Capability Centre

The Central Planning and Monitoring Capability Centre (CPMCC) is responsible for planning, scheduling, monitoring and MIS for all the projects of L&T Power.

All planning functions (including project HO planning and site planning) work as extended arms of CPMCC. The key functions of CPMCC are:

- Standardisation of planning and monitoring processes across L&T Power

- Creating and nurturing a pool of competent planning engineers and their deployment in projects

- Designing and maintaining the Project Monitoring Centre

- Benchmarking (including practices, activity duration, resource utilisation)

- Exception reports for senior management

- Standardisation of review templates, and promotion of effective planning and monitoring using software like Primavera, DMS, E-Alps, et al

- Acting as a single window for reference of all projects, and optimising time and project costs.

Environment, Health & Safety Capability Centre

The Environment, Health & Safety (EHS) Capability Centre has developed operating procedures for effective EHS management system across all functions in L&T Power. Besides implementing the EHS programmes for smooth operations at project sites and offices, the capability centre also identifies training needs to help put the EHS management system in effective use.

It ensures compliance through a system of monitoring and audit. Regular site inspections to monitor and measure EHS performance, incident investigation, non-conformity, status of corrective action & preventive actions, and assisting various functions by deploying specialist EHS resources are the continuous activities of the EHS Capability Centre.

The Centre is testament to L&T Power’s commitment towards health and safety of employees at all project sites.

Commissioning Capability Centre

The Commissioning Capability Centre undertakes commissioning of thermal power plants of L&T Power. The commissioning team endeavours to provide services for the commissioning of power plants conforming to prudent utility practices. The aim is to achieve safe, reliable and environment friendly power plant commissioning and total customer satisfaction.

Besides playing a key role and coordinating in the completion of construction and testing of the plant (including performance guarantee test till the plant is handed over to the customer), the Commissioning Capability Centre also finalises the acceptance standards for taking over from contractors and preparation & approval of commissioning. The Centre is responsible for liaising with the owner’s engineer and O&M group and for resolving all issues coming up at the commissioning stage.