L&T Group Websites

- Corporate

- Corporate – Arabic

- GreenTech

- Heavy Engineering

- Hydrocarbon

- LTIMindtree

- L&T Construction

- L&T Construction & Mining Machinery

- L&T Finance

- L&T Howden

- L&T Hydraulics

- L&T Infrastructure Development Projects Limited

- L&T Infrastructure Finance Company Limited

- L&T Institute of Project Management

- L&T Technology Services

- L&T Kuwait Construction

- L&T MBDA Missile Systems Limited

- L&T Metro Rail (Hyderabad) Limited

- L&T-MHI Power Boilers

- L&T-MHI Power Turbine Generators

- L&T Realty

- L&T-Sargent & Lundy Limited

- L&T Special Steels and Heavy Forgings

- L&T-SuFin

- L&T Valves Limited

- Nabha Power Limited

- Power

- L&T Public Charitable Trust

- Rubber Processing Machinery

- Shipbuilding

- L&T Skill Trainers Academy

The ITER Cryostat

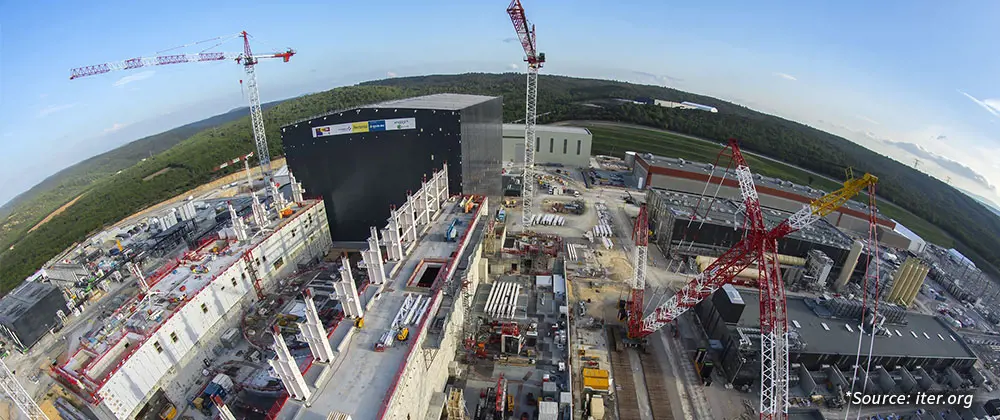

The International Thermo-nuclear Experimental Reactor (ITER) an international collaborative project, involving contributions from seven-member entities - China, European Union, India, Japan, Russia, S. Korea, and USA. ITER is building the world's largest facility to demonstrate the scientific and technical feasibility of fusion power at Cadarache in the South of France. ITER-India - the Indian Domestic Agency (IN-DA) responsible for delivering India's contributions to the ITER Project - is a specially empowered project organization, within the Institute for Plasma Research, which is an autonomous institute under the Department of Atomic Energy (DAE), Government of India.

L&T Heavy Engineering is proud to have been chosen by ITER-India for the manufacturing and installation of the ITER Cryostat.

What is the Cryostat?

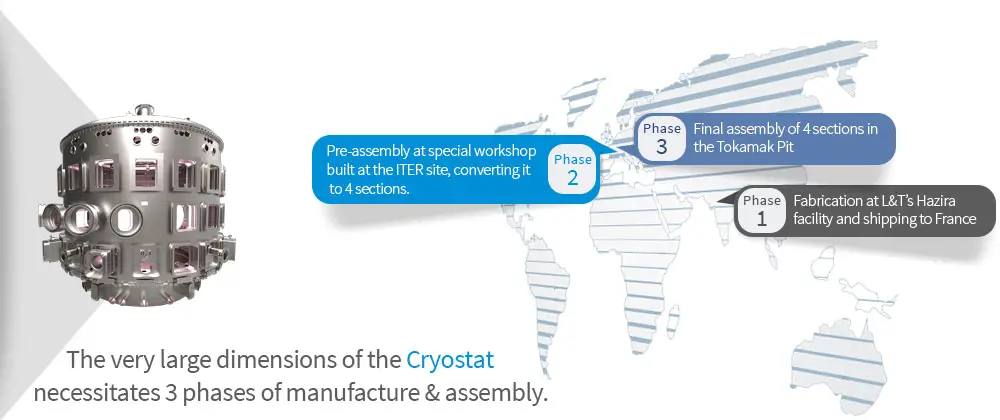

The Cryostat, a key part of the ITER fusion reactor facility, is the World’s largest Vacuum application Stainless Steel vessel. A fully welded cylindrical vacuum/pressure chamber made of stainless steel, the Cryostat is designed with an overall dimension of 29.3-meter diameter, 29.6-meter height and a finished weight of more than 3500 metric tonnes. Thickness of the vessel ranges from 50 mm to 250 mm.

Scope of work

From design concept to detailed engineering, metallurgy, welding technology, fabrication technology, forming, machining, inspection & quality control and finally, the training of the people involved in the project, L&T has been involved in every aspect of building the Cryostat.

- Manufacturing & Supply of Base Section weighing 1060 T, Lower Cylinder weighing 376 T, Upper Cylinder weighing 357 T and Top Lid weighing 606 T.

- Creating a workshop at the ITER site (Cadarache) to assemble the above sections.

- Manufacture and supply of Tokamak Pit Assembly Tools of ~850 T and Loose items of ~ 500 T

- Final installation of Cryostat (04 sections and Loose items) in the Tokamak Pit

In addition, all forgings of the Cryostat are indigenously made by L&T Special Steel and Heavy Forgings (LTSSHF).

This prestigious project is both an opportunity and a showcase for the capabilities within L&T Heavy Engineering, putting us in a select group of global companies. A project that will be a breakthrough in the development of global nuclear fusion energy for mankind.